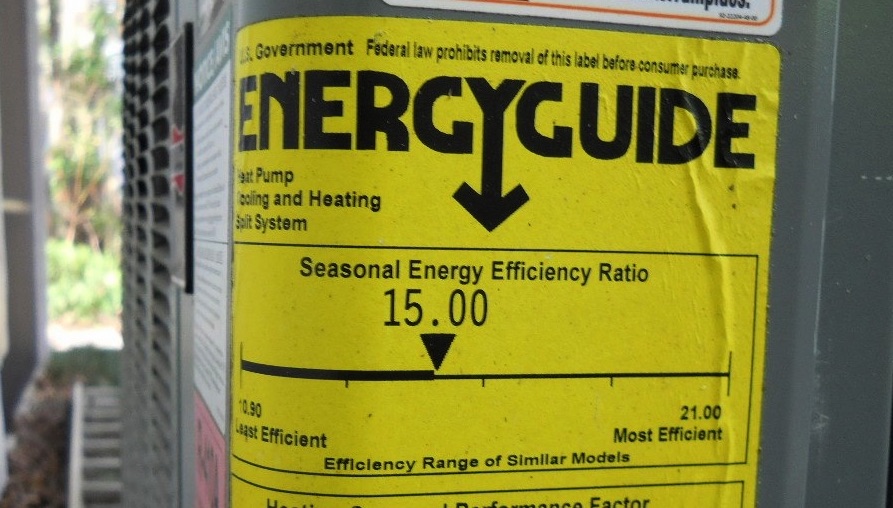

Efficiency continues to be the word. Most heat pump and AC systems in our region are required to be above 14 SEER2 efficiency. A major way manufacturers are tackling the high efficiency requirement is by varying the output capacity of the system based on the amount of heating or cooling needed at any particular time. This is being accomplished with two stage, five stage, even completely modulating compressors, fan motors and gas valves. This greatly improves system efficiency by reducing power/ gas consumption when less output will maintain the needed temperature setpoint.

But speaking of SEER2, what happened to SEER? SEER2 is a more accurate and updated standard for measuring the energy efficiency of air conditioners and heat pumps compared to SEER. SEER2 was introduced in 2023 and takes into account factors like ductwork, airflow, and other real-world conditions that SEER doesn't fully address. As a result, a SEER2 rating will typically be lower than the equivalent SEER rating for the same unit.

Here's a more detailed comparison:

SEER (Seasonal Energy Efficiency Ratio):

- Measures cooling efficiency under ideal, controlled conditions.

- Primarily focuses on the unit's ability to cool under full-load conditions.

- Has been the standard for many years.

SEER2 (Seasonal Energy Efficiency Ratio 2):

- Provides a more realistic representation of energy efficiency by considering real-world conditions.

- Takes into account factors like ductwork resistance, airflow, and cycling, which can impact actual performance.

- Introduced as the new standard in 2023.

- Uses a different testing procedure, including the M1 blower test, which simulates higher external static pressure.

- In essence: SEER2 offers a more comprehensive and accurate assessment of a unit's energy efficiency by incorporating factors that influence real-world performance. This means that while SEER2 ratings might be lower than SEER ratings for the same unit, they provide a more realistic and useful representation of how well the unit will perform in your home.

Transition is the other hot word. The industry is in the process from converting from R410a refrigerant equipment to the new A2L refrigerant family. The two dominant successors from 410a are R454b and R32. R-410A and A2L refrigerants are both used in HVAC systems, but A2Ls are being phased in as replacements for R-410A due to their lower Global Warming Potential (GWP) and improved safety profile. While both are non-toxic, A2Ls are Class 2L (mildly flammable), while R-410A is Class A1 (non-flammable). This change requires redesigns in HVAC equipment and new installation procedures.

Key Differences:

- Flammability: R-410A is non-flammable, while A2Ls are classified as 2L, meaning they are mildly flammable.

- GWP: R-410A has a high GWP (2,088), while A2Ls have significantly lower GWPs, for example, R-454B has a GWP of 466.

- Toxicity: Both are non-toxic.

- Chemical Composition: R-410A is a blend of R-32 and R-125, while A2L refrigerants like R-454B are blends of R-32 and other HFOs like R-1234yf.

- System Redesign: A2L refrigerants require redesign of HVAC equipment, including modifications to materials and safety features.

- Code Requirements: New International Mechanical Code (IMC) requirements for systems using A2L refrigerants include enclosing refrigerant piping within fire-resistance-rated shafts with proper ventilation.

Benefits of A2Ls:

- Lower GWP: A2Ls contribute to a smaller environmental impact by reducing their contribution to global warming.

- Improved Efficiency: A2L systems can be up to 12% more efficient than R-410A systems.

- Lower Refill Costs: A2L systems may require less refrigerant for charging and refills, potentially leading to cost savings.

- Enhanced Safety: While mildly flammable, A2Ls are generally considered safe when handled properly and with appropriate safety precautions.

Implications for Homeowners:

- New Units: New HVAC systems will increasingly be designed to use A2L refrigerants.

- Existing Systems: Existing R-410A systems cannot be directly converted to use A2L refrigerants.

- Professional Expertise: HVAC professionals need to be trained and certified in the handling of A2L refrigerants and the new installation procedures.

- Safety Precautions: Due to their mild flammability, A2Ls require specific safety protocols, including proper ventilation and the use of appropriate safety equipment.